skip

-

Posts

219 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Gallery

Events

Blogs

BMT Wiki

Collections

Store

Posts posted by skip

-

-

It has the same size cab and hood (bonnet) as a R-600, but with a lighter suspension and smaller motor like the chrysler V-8,475N/A scania, and 475 turbo scania

No R400s out here mate, just 600s and 700s. A bloke was tellin me the other day that they used a 185 V8 cummins in some early Macks in the states. Were they in the R400?

-

Hey! Everybody! I am a diesel truck mechanic with 40 years + experience. My first 25 years was spent working on Mack Trucks---specializing on Mack engines---6 cyl. and especially Mack V8's--- 864's , 865's , 866's and early 1005 series (998 cu.in. ), known later as E9's. I left as a heavy line mechanic for dealership's ( Bruckner's in Amarillo , TX--1985-- and factory branch ( San jose , CA in 1983) since then most of my work shifted to PM and repair work for fleets. I began my diesel mechanic's apprenticeship at Dallas Mack Trucks in March of 1968. Moved back to Amarillo , TX in Nov. 1968 and finished my apprenticeship at Bruckner's Mack Trucks there. I moved to San Jose , CA and started work for Motor Truck Distributors ( A Mack factory branch ) in Aug. 1974. It seemed I had an above average apptitude for working on engines--- I started working on naturally aspirated 864's in early 1970---nobody else liked to work on the V8's---but, I did. Then , Mack came out with the Maxidyne 865 V8 at 325 hp and a little later the Thermodyne 866 V8 at 375 hp. The two engines are virtually identical inside and out. There were some production problems on the early 865's and 866's that required extensive modification in the field and these were mostly carried out when these engines came in for a rebuild. Well! WHEWW! that was a quick synopsis for now. One more thing ---I really liked these engines and when properly set up ( advance timing 6 degrees--- a couple of turns on the fuel rack in the injection pump---raise injector pop pressure 10%----set exh. valves loose--- .028 not .024; set int. valve tight----.012 not .016 , shim the puff limiter valve with 2 .100 shims--- bring the RPM's up to 2400 RPM. These engines would come alive like you wouldn't believe. I set an 866 up for a produce hauler that was putting 425 hp to the wheels!!!!! And as long as he kept the RPM's on the engine under 1800 on the flat stretches of highway ( approx. 63 MPH ) with Mack 3.17 rearends, he was getting almost 8 MPG!!! And there were other similar V8's I set up this way for Owner/operators. Of course these modifications were highly illegal by the CA. and FED EPA, but I didn't care at the time--------I just knew these engines could run if you set them up right. See Ya! Have any qestions --just ask. mackV8mechanic

Gday mate how are ya? Great to have you on board and thanks for sharing the V8 knowledge. I might have a question for you from time to time with a couple of 864s in need of repair. Im also after an 865 to go back into an F model. Would you know if you can still buy liners for those engines? Thanks mate, Skip.

-

1

1

-

-

We just shut the doors,and run a wide strap through the door ,and use a excavator too pick up and move it around, ain"t damaged one yet!!!

Gday all. Sorry i havent been about for a couple of days. Thanks to everyone who wrote back, it gives me some pretty good ides to go on with. Keep on truckin eveyone, cheers. Skip

-

Gday everyone. This may seem a stupid question but in your experiences, what is the best way to remove and refit an R model cab? Would you use a large beam through the doors an sling the ends of it? Thanks for any help. Skip

-

Boring? I think not! The thought of a Buzzin' Dozen in a Mack will give me sweet dreams tonight. Good Luck Rob, and keep us posted. Thanks, Brad

How are ya mate? There is a bloke out here in Australia who is rumoured to be importing an LTL with a V12 Halls-scott. Do you know if this was a genuine fitment? I dont know too much about the early ones, but Im lead to believe it is original. Cheers mate, Skip

-

Our Quantum with an EA7-470 (think the A designates Australian spec) is being a pig yet again. Local dealer has washed their hands of it (can't blame them) and I have to tried to fix it. Has a complete lack of power, as it only does 95km/h (about 55 mph) flat out bobtail! The turbo barely makes a squeak and it's just so flat and unresponsive to drive it's ridiculous. To be honest it feels like the fuel lines and air filter are completely blocked(but they're not, done all those checks). Mechanically it's fine, had an in chassis rebuild in March and services and 2 top end checks and adjustments since then. Time to look at sensors, however not having a workshop manual or wiring diagram doesn't help. The co-pilot read out says it's at 100% engine load bobtail at about 1400 rpm and that matches where it stops pulling too, so I am pretty sure it is a bad sensor. But which one??? Any help would be greatly appreciated.

Its obviously not bringing up a code? Our Qantum was goin like a dog and the local mack blokes put an intercooler in it, but every now and then it would flash up with an injector code. So obviously the intercooler didnt work. We later found the gear drive in the fuel pump was floating around and not giving it enough fuel. Something to check. Also maybe check the speed sensor on the back of the box.

-

Gday all. Im wondering if anyone has any ideas or had experience with making or refurbishing name plates and tags. Ive got a few on my Flinstone that Id like to fix up. One is the engine operating range plate on the dash for a V8 -1700-2300RPM. Also the TRQ7220 shift plate. On the engine there is a plate on each front valve cover with Thermodyne Diesel and patent numbers. Id like to get them done in black an white again, and the same goes for the pump timing and valve clearance specs plate on the top of the auxilliary drive. And does anyone know what the piece is that fits into the block just above the flywheel housing on the END864, My guess is a breather, but it has breather pipes on the valve covers. Anyway this little piece also has a decal on it, but it has been rubbed off. Does anyone know what it said? Any advice on any of this stuff would be great. Thanks everyone, Best regards, Skip

-

We have a limited supply of custom acrylic shift knobs made with actual Mack Bulldog hat pins molded into the knob! They are completely smooth on the outside and are available in several different colors. All balls have 1/2" course threads for mounting. Price is $80 each for the Bulldog pins and $85 each for the enamel logo pin knobs. Special orders are possible but will take several months. If you want one of these designs, call me NOW!! I only have 2 of each color pictured...

Black with metal flake

Red with metal flake

Green with metal flake

Solid black

Solid white with enamel logo pin

Solid white with Bulldog pin

Gday Barry. They look great mate. Can you ship them to Australia? If so I would grab 2 of the green ones. Cheers, Skip

-

I have a 71 F model with a end864 (naturally aspirated ) It has a spicer twin disk . The head gaskets do not have fire rings. I took mine off the road, its to hard to get parts for the 864. I even bought a complete engine for it, just for parts. The truck is all original, I have line sheet for it. I now use it for a boom truck in the shop.

Where are you based mate? I thought they had fire rings, Ive got a set of gaskets there and Im sure that they have removable rings. I must be wrong. Thanks for that. Has that been changed to a twin plate? I have a 71 F785 with a cable operated push clutch. Skip

-

Thanks Skip,

Very informative. I did not appreciate the difference between the 864 and the 865/866.

Can you comment on the head gasket question? Was there a problem with blown head gaskets on these old motors? Do the 864 or 865/866 have fire rings?

Pete

Im not totally sure on the motors doing head gaskets, there arent many around here any more. The 865/6 had a bit of trouble if heads werent re-torqued periodically. I think a lot of blokes out here used to re-torque them around 50-60thousand Kms. Im not sure about the 864, but every block Ive seen has major shuffle marks on the deck surface, so I would say they were in the same boat. The 864s also cracked around the counter bores and between the counter bore and some head stud holes, as there is only about 3/16" surface area. They have fire rings. Ive just had a block repaired and we paid really close attention to these areas I mentioned. Do you have a T864? There were only ever 2 or 3 in Australia. The only one Ive seen is on ebay in an R719.

-

Found new R model roof panels, gutter panels. for these old girls, they probly do other bits to.

regards Grant

How are ya mate? Where'd you come across them? and are you getting rid of them? Dave Willis

-

So the ENDT864 was the twin turbo?

Did the 865 and 866 have the same compression ratio as the ENDT864, and the same piston?

Is it possible to install a an E9 injectors into the 866 head?

Will E9 exhaust manifolds work on the 866 head?

Pete

How are ya mate? E9 injector wont fit into a 2 valve head. It goes in between the valves under the tappet covers whereas an 865/6 goes in on a slant outside the tappet cover, like a 6cyl 2 valve. E9 exhaust wont fit an 864/5/6. They have 4 ports per side whereas the old ones only had 2. And the 865/5 manifold wont go on an 864 either, as they have 4 bolt holes instead of 2. A pain in the arse.

I have never seen a T864 so I couldnt comment on compression ratio or piston type, but I would nearly be certain the pistons wont be interchangeable with an 865/6. The 864 series was always grouped with the 711 series. While the block and front cover looks similar between the 2 V8s there arent too many parts that are interchangeable. The Auxilliary drive was similar and you can put a Vee pump on an 864 but there was a different housing on some 865s just to make life complicated. Hope that rant wasnt too painful. Good onya mate. Skip

-

My 65 B61ST has a kingpin that refuses to take grease even after using an air pressure grease gun. I've resisted trying to heat it since the front axle is off a 91 Mack and may have plastic. The truck sat for quite a while before i got it and steering was awful until i got some grease into it. Turns left normally now, but right turns are a real chore. Thought on how to rectify this issue?

If its difficult to turn make sure the adjusting nut at the bottom hasnt been wound uo too tight.

-

Hello, i posted chassis number above, its to old for the spare parts boys, they are almost straight out of school.

and no id #s on front of axle, it only has casting numbers. the other two trucks do have these numbers tho.

Gleemans were great to deal with, they put me onto a group in perth who can help. may have found replcement roof skins to., will know more tomorrow. and they know what a microfish is, so i dare say i am in luck.

Mate if you have any more trouble, ring Neil Owen in spares at Mack Brisbane. Hes great with the old stuff. Hes been there over 30 years I think. 0737183527 is his number. Regards Dave Willis

-

Hi Werkhorse, The FR model was fitted with an F model type cab, either Day-cab or Sleeper Cab in either Steel or Fibreglass, that was a designated Right hand drive, mounted on the standard Australian R Model Chassis. All the plumbing on the FR was the same as an R Model with extension hoses and wiring etc. to fit to the F cab. The FR cab did not have the cross-over steering arrangement that the older F Models had. The F Models had a wider chassis than the FR Models so they had different (wider)rear engine mounts. The set back front axle was only introduced near the end of the production of FR Models, just before the Cruiseliner was released. Best regards-Michael.

Thats pretty well spot on mate, although we have a '71 F785 and it has full power steering with the steering box mounted behind the front wheel. I havent seen another like it, but it is a genuine setup. I dont think the F models with a setback front axle were an FM, but Ive certainly been wrong before. It was a bit of a trend at the time for different weight laws I believe, Leader did the same thing. There werent too many out here.

The air ride cab I dont think ever came out here, Our FR786 coolpower has a set of shockies inside 2 coil springs with a sway bar. Someone has also put an extra set of shocks right at the back of the cab so it gives a pretty good ride. Ive seen a couple of European F model cabs and they have an extra deep toolbox on the drivers side(RHS). It is nearly as big as the one on the LHS.

And another interesting part of the plastic cabs, the air intake for the engine used to go through the roof of the cab via a scoop at the front and down to an aircleaner barrel on the RHS under the back of the cab. It wasnt a very successful idea as it was fairly noisy and it restricted air flow, particularly on the V8s. Most of them were changed to an air ram up with the smoke stack. The early cabs had fibreglass doors and panels but the later ones went back to a steel door. They were interchangeable.

Good to know though, an F model with a coolpower is still a bastard to get the radiator out of!! Some things never change. Skip

-

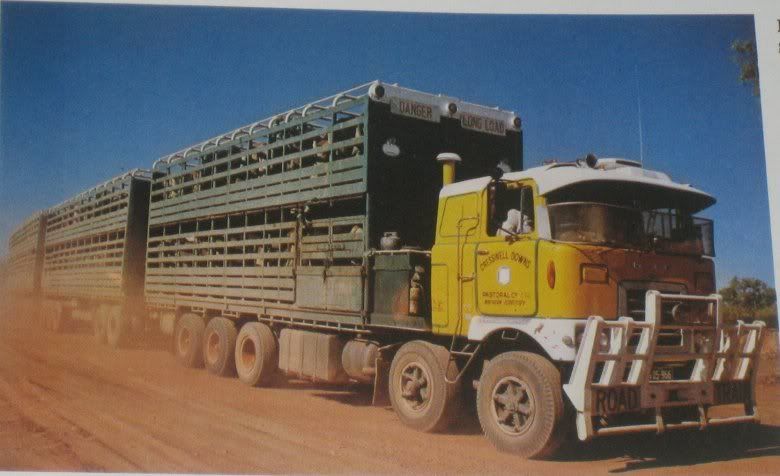

Don't know if you like Australian trucks but here is one impressive F model pulling a livestock road train:

That grille was only available on V8 powered F models in Australia and New Zealand. I also have pictures of a few 6x6 and a 4x4 F models from down under as well.

Also of note the now defunct Australian truck maker Leader used the F cab on one of their trucks. They were used as twin steer 8x4 dump trucks and had CAT 3208 boat anchors and a fuller 13 speed behind it.

How are ya Thad? Those grilles were available on all F models with the fibreglass cab, 6 or 8 cylinder. They were made by a crowd in Melbourne called Reinforced plastics, who also made the cabs for the 3800 series Atkinsons. Notice on that F model in your picture the extra long grab handle? they were only available on the plastic cabs. As for Leaders, they were designed by the bloke who brought Macks into the country, Cyril Anderson. He wanted a cheap, light truck for short haul work and Mack wouldnt make him one so he built one. Were available with 3208, 3306 and 3406 Cat engines, and the last had 692 GMs in them. I should have a couple of F models in my gallery, an FR686 and an F785. Cheers mate, Skip

-

i have been told of people getting 500hp out of these old 864,865,866 engines, how?

regards Grant

Gday all. I dont think you would get 500 out of an 864. Ive heard of a few 866s being taken out to 450-500. The 865 was a Maxidyne engine with lower hp than the 866 but more torque. I have heard of blokes using an E9 pump on an 866 but not an 865. As for the T864 the rotary pump was a bit troublesome and the twin turbo setup was fairly complicated so they canned them both and went for the single turbo and vee pump. The T864 was 300hp as already mentioned and out here the 864A was rated at 280hp in the R models and a few F models. Cheers skip

-

Yeah, as I said in one of my earlier posts, Mack book time is 5 hours to REMOVE the sump.

What year model is it mate? The early ones were built on Renault cahssis rails and they were a nightmare. Weve got 2, one with an ISX Cummins in it and the other with a 410 Mack motor, and they are both on CH rails, and arent too bad to work on. Ours are 2004 and 2006 models respectively

-

G'day all. My name is Chris and I am from Port Pirie, South Australia. I am the workshop manager/mechanic for a small transport company here that does general and refrigerated freight to and from the local area, as well as oversize loads around the state. The fleet is being updated constantly consisting of mainly Volvo FH prime movers. At last count it was 5 Volvos (4 FH 12's, 1 FH16), 2 Scania 3 series ( a 113 & 143), an old 112 slimline scania yard truck, a Mack Quantum (Renault cab and chassis with a Mack EA7-470 engine, 18 sp r/ranger, Meritor diffs), 1 AT9500 Sterling 550 C-15 Cat 18 sp 4.33 Meritor 46,000lb air bag rear, 2 Nissan/UD rigids (1 with a crane fitted), 1 Isuzu rigid as well as numerous trailers of all configurations, last count was about 14 from memory. I have 1 bloke in the workshop with me to help with the maintenance, which gets pretty full on at times. We have a new drop deck, widening float ordered that should be here in a couple of months, built to spec. As we are in the driest state in the driest continent on earth, we have our own unique set of challenges to meet, and at the moment are in the worst drought in history. Summer temperatures here get up to the mid forties (that's 110 deg F) on a regular basis and there are more dirt roads than sealed once you leave the highway, so its hard on the gear.

The boss is talking of trading in the Quantum (happy dance) in the next few months for something else to do the dirty work. That is the oversize, dirt road, heavy loads. And he is talking CH or maybe even Superliner with 470 to 500 hp. Here's hoping. A Titan would be nice, but about as much chance of that as me flying to the moon tomorrow.

I have found this site and the forums very helpful and hope my input has been of assistance as well. Some of my posts might come off as being pretty biased, but i am only drawing on my experiences over 25 years in the transport industry here not only as a mechanic, but as a driver as well. I have owned my own truck which I restored from the ground up, a 1974 White 4000. Ended up with a 400 NTC Cummins, 15 sp o/d, 40,000lb hendrickson & rockwell diffs @ 4.11 ratio. Quick little toy. The Engine was a 2nd hand USA import that was a Big Cam 3 & 4 hybrid.

Hope I haven't waffled too much and hope to chat to you all soon,

Chris W.

Gday how are ya mate? Thanks for signing up its good to have another Aussie on deck. Im from over in NSW so Im just over a stones throw away. Would like to see the old white, if we didnt have Macks to do up a white would be my first preference. All the best mate, catch up with ya. Skip

-

Gday all. Ive got a couple of END864s that Im tryin to get going. and Im like the boy with the wheelbarrow- Ive got the job in front of me. Both of my blocks have cracks between the head stud holes and the counter bores. If anyone is familiar withe the deck surface they will know that there is a very narrow area between these 2 holes, maybe 1/4" at best. As blocks are scarce as hens teeth my options are limited. Bearing in mind I want to keep these engines in the trucks as they are quite rare. One machine shop has the idea of boring the hole out and pressing an insert into it. No one seems too keen to gouge it out and weld it then cut new counter bores out. Im wondering if anyone has encountered similar trouble and what they did to dig themselves out. Thanks everyone, Skip1

-

I didn't like that steel line either, the one that comes out of the block and into the compressor and carries coolant. So I ran a flexible, high pressure hydraulic hose when I replaced the compressor and governor. But maybe you are talking about a different line?

That wasnt the line I was referring to mate but you're right, it can be a pain too. Every time you take it off you have to replace those thick orings. The line I was referring to is the discharge line that goes to the wet tank. They used to use a steel pipe and then it joined onto a flexible hose when some of the heat had gone out of the pipe. Cheers mate, Skip

-

the valve set is the same,you simply set the jake as your seting the valves the setting is depenant on hp 85 thou comes to mind!

I know on an E-tech 370-470hp the Jake setting is 17 thou. I dont know about the mechanical engines though.

-

It seems like it takes awhile for pressure to build in the system. How long would you expect it to take for an older truck to build up pressure, and what could be causing the delay? I replaced the compressor and governor, the dryer and fixed several leaks.

They do take a while mate, as everyone else has mentioned. One thing you can check though, if its an E6 engine, they have a steel pipe on the discharge side of the compressor, and it has 2 90 degree bends in it which are prone to building up with oil and gunk. This will restrict the flow in a big way. Ive cured this by running a flexible hose straight to the wet tank. It will probably have a flexible hose on it already that joins to the end of the steel pipe and it can be porous from being hot and with the sound of the engine running you will never hear it leaking. you can remove the hose from the compressor and hook it into a separate air supply and if it leaking you may hear it that way. See how you go mate. Cheers. Skip

-

What about the bridge adjustment ? Do ya set em so you just start to fell it rise as on other engines?

Yeah mate thats the go, just wind the adjuster screw down until it touches and continue a further 60 degrees(1 flat) and lock the nut up at that

G'day From An Aussie Mack Freak!

in Introduction Forum

Posted

Gday mate how are ya? Dave from NSW here good to have you on board. If you like Macks youre in the right place. Catchya round the traps. Skip