oldspwr

-

Posts

151 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Gallery

Events

Blogs

BMT Wiki

Collections

Store

Posts posted by oldspwr

-

-

- Popular Post

- Popular Post

This is really an outstanding restoration! Thanks for taking the time to document and share your progress. I really enjoy reading build threads...

-

4

4

-

Sorry, I didn't realize this was an old post...

Tom

-

Can you share any pics of how you modified the sleeper? Would love to see how you made the exhaust cutout!

-

-

This steering wheel is very similar to the ones in my Brockways. The 50's vintage 100 series Brockways used a 20" Sheller wheel with a 7/8" splined shaft. I always thought it was odd that they put the (2) 5/16 threaded holes in offset from the center. You can't use a traditional steering wheel puller to remove the wheel.

-

1

1

-

-

-

-

-

-

-

There was a discussion in the antique group in regards to 'Old Mack Engine' and Brockway's Huskidrive was mentioned. This is when Brockway used a custom torque 270 Cummins, a 5 speed Fuller trans and a 2 speed rear. Brockway used (2) dogs on each grill to symbolize this, both on the conventional and cabover trucks. It was also carried over the the 700 series trucks but fairly uncommon. Here is the factory literature...

-

2

2

-

-

I believe you are correct in that the factory branches were owned directly by Brockway. There were 2 factory branches not far from me, 1 in Kingston PA and the other in Scranton PA. Both buildings still stand today.

Mack purchased Brockway in 1956 and its my understanding that it was autonomous. In other words Brockway was able to make their own decisions, etc.

-

5 minutes ago, 67RModel said:

I have always wondered who/where the local Brockway dealers were in Pittsburgh, PA. I have asked may old timers and nobody knows or seems to remember. I now understand why: It looks like there weren't any. This is hard to believe considering how large of an industrial complex Pittsburgh and the surrounding areas were at the time of this publication. I always though Brockway had a much larger presence than they apparently did. What were their total yearly production numbers compared to Mack?

They had a factory branch in Pittsburgh, it's listed on the first page (but its hard to read). The address was 4367 Campbells Run Road, 15205.

-

1

1

-

-

I have new a Raybestos 15" 1-1/2" 10 spline clutch disc that is labeled VL 1517 10 2 79. I'm guessing VL 1517 is the part number and 10-2-79 is the date of manufacturer. It came in a Mack box that's in really tired shape. The part number on the box may have been 368D or 3680. I bought it for my 55 Brockway with the 5 speed Fuller 5A430 trans. The only problem is that it's too thick so I can't use it.

Would anybody be able to identify this clutch based off of the Mack or Raybestos part number? I tried to find a vintage Raybestos clutch book but the only one I could find was on ebay for $300...

Any help would be appreciated!

Tom

-

-

-

-

-

14 hours ago, mrsmackpaul said:

I think they are a motorbike jack, not sure though

Hi Paul... You're right, it was sold as an ATV/4 wheeler/Motorcycle jack. A friend gave it to me after I wired his 39 Ford Deluxe years back.

-

1

1

-

-

Just a quick follow up on the difference in the pinions...

When I removed the driveshaft from the 6.71 rear in the truck, I was able to read the pinion number which was 41967. This was one digit higher than the ring gear, 41966. So I can assume that the pinion for the 5.43’s was 41961. But the head of the pinion on original 5.43 was really pitted. You could make out ‘Eaton’ and 7 and 38 (38/7=5.43) but that was about it. So when I googled the ring gear number and found Weller’s site, I just assumed the pinion was 48820. Regardless, it all worked out at the end of the day...

Just for comparison, the new pinion vs. the old...

In the mean time I decided to make a ‘jig’ to help remove the pumpkin from the truck using my 4 wheeler jack. I’ve used this jack a 1000 times for different things (like installed the fuel tanks, etc.) but never on a 4 wheeler. So using some flat stock and angle on hand I made something to support the base and the pinion so that I could roll the pumpkin out...

1

After that was done we drained the oil and then made a few dowels out of some old bolts...

And then we removed the pumpkin...

The jack actually worked pretty well...

To help work on the rear I cut a few other pieces of angle...

And then set the pumpkin on the bench...

More to follow....

-

2

2

-

-

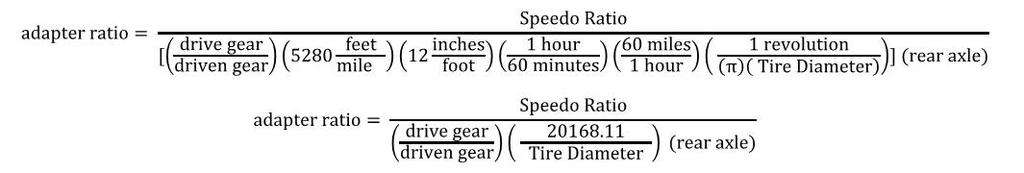

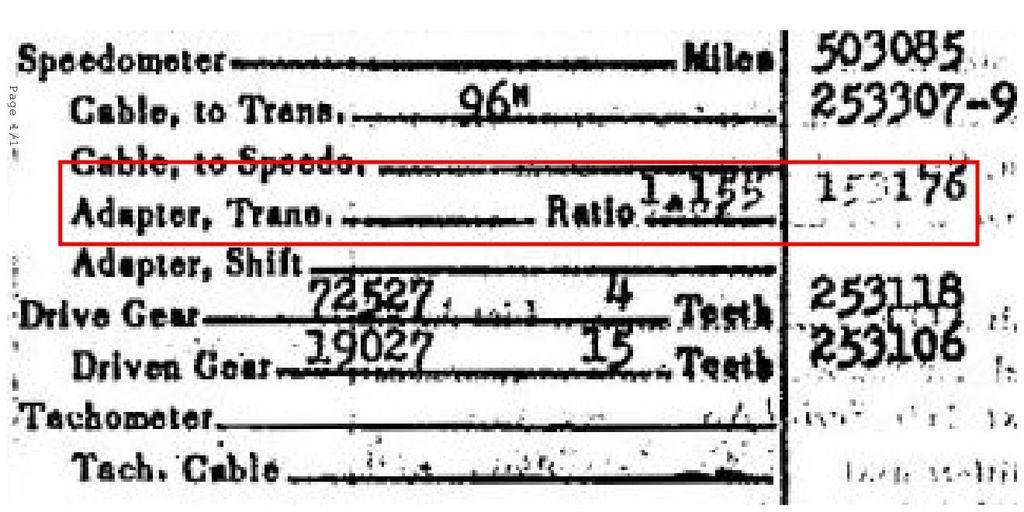

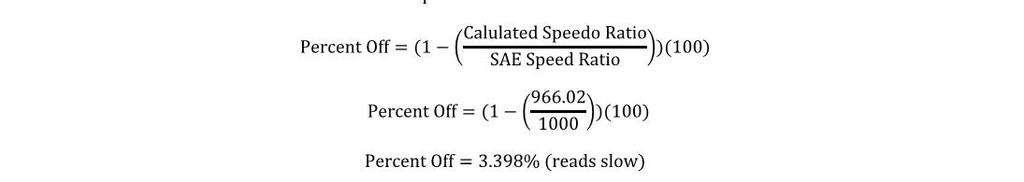

But now we can reconfigure the formula to solve for the speedometer adapter we need. This is helpful if you are making a tire change or a rear axle change.

And again using my Dad’s truck for reference, we can input all of the variables but this time using 3.70 for the gear ratio...

Rear axle ratio 3.70

Rear Tire Diameter 40.5”

Transmission Drive Gear 4 teeth

Transmission Driven Gear 14 teeth

So it looks like I need an adapter with a 1.8995 ratio of something close.

RATIOS AVAILABLE FOR 8800 SERIES Straight and Offset ADAPTERSSLOW DOWN RATIOS AVAILABLE CORRECTS FOR SPEED UP RATIOS AVAILABLE CORRECTS FOR

0.9822 1.8% FAST 1 0% CORRECTION

0.9743 2.6% FAST 1.0181 1.8% SLOW

0.9705 3% FAST 1.0263 2.6% SLOW

0.9642 3.7% FAST 1.0303 3% SLOW

0.9615 4% FAST 1.037 3.6% SLOW

0.9578 4.3% FAST 1.04 3.9% SLOW

0.9523 5% FAST 1.0439 4.3% SLOW

0.9457 5.7% FAST 1.05 4.8% SLOW

0.9444 5.8% FAST 1.0574 5.5% SLOW

0.9333 7.1% FAST 1.0588 5.6% SLOW

0.9273 7.8% FAST 1.0714 6.7% SLOW

0.9183 8.8%FAST 1.0784 7.3% SLOW

0.9122 9.6% FAST 1.0888 8.2% SLOW

0.9058 10.3% FAST 1.0961 8.8% SLOW

0.9 11.1% FAST 1.1038 9.5% SLOW

0.8974 11.4% FAST 1.1111 10% SLOW

0.8947 11.7% FAST 1.1143 10.3% SLOW

0.8888 12.5% FAST 1.1176 10.6% SLOW

0.8824 13.3% FAST 1.125 11.2% SLOW

0.8814 13.4% FAST 1.1333 11.8% SLOW

0.8797 13.6% FAST 1.1344 11.9% SLOW

0.8769 14% FAST 1.1368 12.1% SLOW

0.8684 15.1% FAST 1.1404 12.4% SLOW

0.8667 15.3% FAST 1.1515 13.4% SLOW

0.8653 15.5% FAST 1.1538 13.4% SLOW

0.8626 15.9% FAST 1.1555 13.5% SLOW

0.8571 16.6% FAST 1.159 13.8% SLOW

0.85 17.6% FAST 1.1667 14.3% SLOW

0.8462 18.1% FAST 1.1765 15% SLOW

0.84 19% FAST 1.1818 15.4% SLOW

0.8333 20% FAST 1.1905 16% SLOW

0.8319 20.2% FAST 1.2 16.7% SLOW

0.8241 21.3% FAST 1.202 16.8% SLOW

0.821 21.7% FAST 1.2133 17.6% SLOW

0.8105 23.3% FAST 1.2179 17.9% SLOW

0.8095 23.5% FAST 1.2338 19% SLOW

0.8 25% FAST 1.2353 19.1% SLOW

0.7894 26.6% FAST 1.25 20% SLOW

0.7785 28.4% FAST 1.2666 21.1% SLOW

0.7778 28.5% FAST 1.2844 22.1% SLOW

0.7764 28.7% FAST 1.2857 22.2% SLOW

0.7754 28.9% FAST 1.2878 22.4% SLOW

0.7719 29.5% FAST 1.2896 22.5% SLOW

0.7714 29.6% FAST 1.2955 22.8% SLOW

0.7692 30% FAST 1.2963 22.9% SLOW

0.7647 30.7% FAST 1.3 23.1% SLOW

0.7555 32.3% FAST 1.3077 23.5% SLOW

0.7511 33.1% FAST 1.3235 24.4% SLOW

0.75 33.3% FAST 1.3314 24.9% SLOW

0.7466 33.9% FAST 1.3333 25% SLOW

0.7444 34.3% FAST 1.3394 25.3% SLOW

0.7352 36% FAST 1.3434 25.6% SLOW

0.7333 36.3% FAST 1.36 26.5% SLOW

0.7222 38.4% FAST 1.3636 26.7% SLOW

0.72 68.8% FAST 1.3846 27.8% SLOW

0.7143 38% FAST 1.3889 28% SLOW

0.6947 43.9% FATS 1.4 28.6% SLOW

0.6944 44% FAST 1.4394 3.05% SLOW

0.6923 44.4% FAST 1.44 30.6% SLOW

0.6862 45.7% FAST 1.4444 30.8% SLOW

0.6842 46.1% FAST 1.4571 31.4% SLOW

0.68 47% FAST 1.4615 31.6% slow

0.647 48.3% FAST 1.4706 32% slow

0.668 49.7% FAST 1.4835 33.6% slow

0.6666 50% FAST 1.497 33.2% slow

0.6617 51.1% FAST 1.5 33.4% slow

0.6561 52.5% FAST 1.5111 33.9% slow

0.65 53.8% FAST 1.5241 34.4%slow

0.6481 54.2% FAST 1.5385 35% slow

0.6471 54.5% FAST 1.5429 35.2% slow

0.6302 58.6% FAST 1.5455 35.3% slow

0.625 60% FAST 1.5866 37% slow

0.619 61.5% FAST 1.6 37.5% slow

0.6049 65.3% FAST 1.6154 38.1% slow

0.6037 65.6% FAST 1.6531 39.6% slow

0.6 66.6% FAST 1.6564 39.7% slow

0.5952 68% FAST 1.6667 40% slow

0.5929 68.6% FAST 1.68 40.5% slow

0.5882 70% FAST 1.6863 40.8% slow

0.5833 71.4% FAST 1.7 41.2% slow

0.5789 72.7% FAST 1.7143 41.7% slow

0.5777 73% FAST 1.7273 42.2% slow

0.5709 75.1% FAST 1.7307 42.3% slow

0.5701 75.3% FAST 1.7515 42.9% slow

0.5625 77.7% FAST 1.7538 43% slow

0.5607 78.3% FAST 1.7778 43.8% slow

0.5555 80% FAST 1.7831 44% slow

0.5392 85.4% FAST 1.8 44.5% slow

0.5357 86.6% FAST 1.8545 46.1% slow

0.5321 87.9% FAST 1.8667 46.5% slow

0.5294 88.8% FAST 1.879 46.8% slow

0.52 92.3% FAST 1.8889 47.1% slow

0.5185 92.8% FAST 1.9231 48% slow

0.5131 94.8% FAST 1.9286 48.2% slow

0.5108 95.7% FAST 1.9487 48.7% slow

0.5102 96% FAST 1.9576 48.9% slow

0.5032 98.7% FAST 1.96 49% slow

0.5018 93.3% FAST 1.987 49.7% slow

0.5 100% FAST 1.993 49.8% slow

0.4887 104.6% FAST 2 50% slow

0.4859 106% FAST 2.0462 51.1% slow

0.4825 107.2% FAST 2.0606 51.4% slow

0.4761 110% FAST 2.0727 51.7% slow

0.4681 113.6% FAST 2.1 52.4% slow

0.4667 114.2% FAST 2.1361 53.2% slow

0.4621 116.3% FAST 2.1429 53.3% slow

0.4561 119.2% FAST 2.1636 53.8% slow

0.4503 122% FAST 2.1923 54.4% slow

0.45 122.2% FAST 2.2208 55.02% slow

0.4444 125% FAST 2.2222 55% slow

0.4427 125.8% FAST 2.25 55.6% slow

0.4343 130.3% FAST 2.2587 55.7% slow

0.4313 131.8% FAST 2.303 56.6% slow

0.4286 133.3% FAST 2.3182 56.9% slow

0.4186 138.8% FAST 2.3333 57.1% slow

0.4135 141.8% FAST 2.3884 58.1% slow

0.4105 143.5% FAST 2.4182 58.6% slow

0.4 150% FAST 2.4359 58.9% slow

0.3961 152.4% FAST 2.5 60% slow

0.3882 157.5% FAST 2.5245 60.4% slow

0.386 159.9% FAST 2.5758 61.2% slow

0.3746 166.9% FAST 2.5999 61.4% slow

2.6694 62.5% slow

More to follow...

-

1

1

-

-

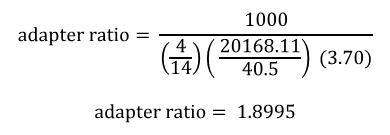

Speedometer Adapter Ratio

Every Brockway truck that I have purchased had some kind of Stewart Warner adapter on the transmission. These are typically covered in oil but once you clean them up you can usually find the ratio stamped on them. This also came from a Brockway manual. This shows (3) different style speedometer adapters (or what they called ‘correcting adapters’). I typically see the ‘box type’ on Brockways and the ‘straight type’ on GM cars and trucks.

RL]

RL]

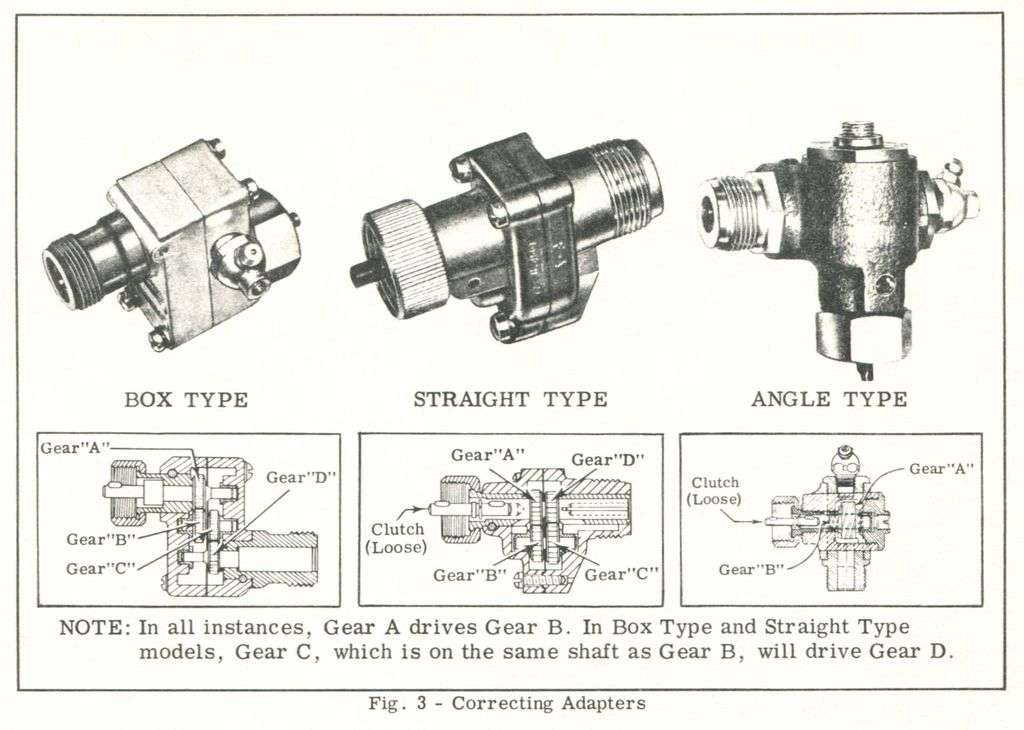

If we go back and reference the pic for the 155T, the ratio was 1.155...

So there are 2 options available to correct your speedometer. The first is to replace the drive and / or driven gears within the transmission and the second is to replace the speedometer adapter. Years ago when I was working on cars, it was easy to replace the drive and driven gears within the TH350, TH400 and 200-4R and 700-R4 transmissions. In fact I had a coffee can full gears I collected from the junkyard. But with the larger Fuller / Eaton / Roadranger transmissions, it’s not really that easy. And I honestly do now if different gears are available. So the most practical solution is to replace the speedometer adapter. To help determine which adapter ratio we need, we need to work through a formula...

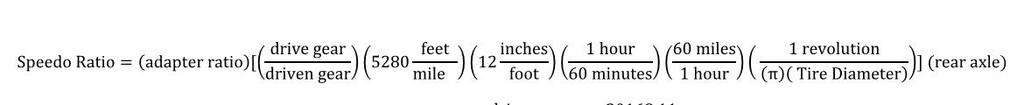

Although this is a busy formula, I will work through it to simplify it. We are going to solve for the speedometer ratio which we know should be 1000 rpms.

And then we can simplify it to this...

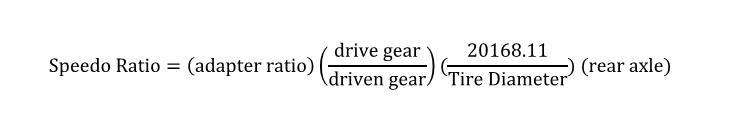

So using my Dad’s truck for reference, we have the following variables:

Rear axle ratio 4.10

Rear Tire Diameter 40.5”

Transmission Drive Gear 4 teeth

Transmission Driven Gear 14 teeth

Speedometer Adapter 1.656

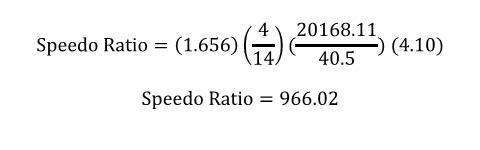

So we’re actually pretty close to 1000. You have to keep in mind that in some cases it will be difficult to get it to exactly 1000 due to the gear combinations available for the speedometer adapters. To understand just how close we are, we’ll calculate the percentage...

In a majority of the Brockway chassis records I looked at, they ranged from 0 to 6% off so we are in the ball park here.

-

I posted this a while back on the Brockway Message Board and figured it may help some folks here...

This post is a little more technical in depth (well actually a lot more...) but may help a few folks out. I am getting ready to replace the 4.10's in my Dad's 361 with 3.70's to reduce the rpm at 65mph. Once I do that the speedometer will be off so I'll need to correct it. With the 4.10's in the truck the speedometer is fairly close and I confirmed this with a GPS based on my iPhone. If your speedometer is way off then this may be a good way to approach it.

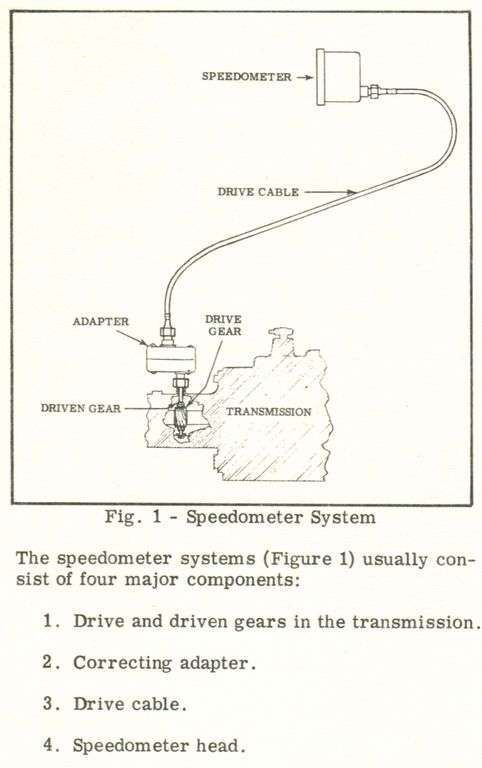

Let’s start with the basics...

Based on SAE standards, at 60 mph the speedometer should turn 1000 rpms. This is a constant value that is true for automotive speedometers, including the ones used in Brockways as manufactured by Stewart Warner. To determine the correct ratio there are (4) variables we need to consider. These include the rear axle ratio, the rear tire diameter, the drive to driven gear ratio within the transmission and the ratio of the speedometer adapter.

Rear Axle Ratio

Most guys are familiar with what their rear axle ratio is. If not, sometimes there is a tag on the rear housing. In this case we are looking at 3.90’s...

In some cases look you can look at the head of the pinion. Typically the number of teeth of the ring and pinion is stamped on the head of the pinion. It this case it's 7 and 38, so there are 7 teeth on the pinion and 38 teeth on the ring gear. This equates to 38 / 7 = 5.43.

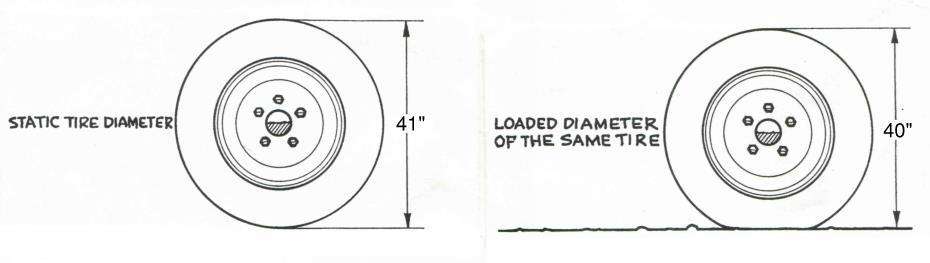

Rear Tire Diameter

For the rear tire diameter, I typically place a straight edge across the top of the tire and measure to the ground. By doing it this way you will account for the 'load' on the tire. In reality, the best way is to measure the radius from the center of the wheel to the ground and multiply it by 2, but it is difficult to figure out the exact center (unless you mark your center cap or something like that.) Regardless measuring the diameter in this manner will get you very close.

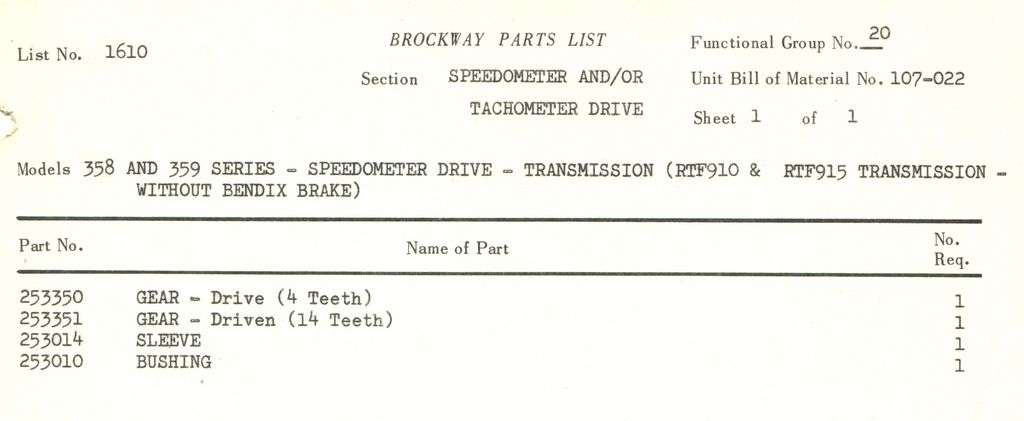

Transmission Drive & Driven Gear

Within the transmission, where the speedometer cable or adapter connects to the transmission, there is a set of gears. One gear is located on the output shaft and this is called the drive gear. The other gear is what the cable or adapter connects to and this is called the driven gear. The drive gear typically has between 4 and 6 teeth and the driven gear has between 12 and 15 teeth.

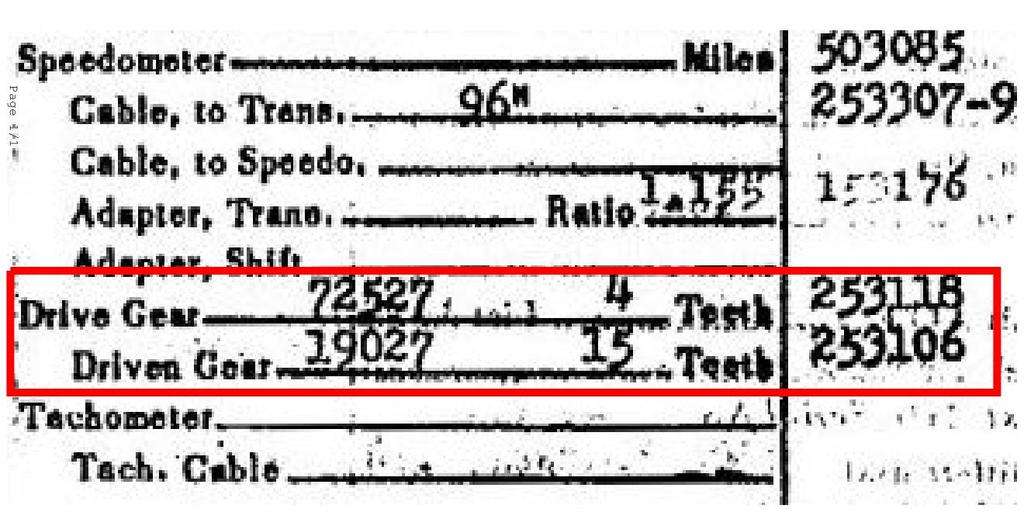

I realize it is difficult to determine what your drive and driven gears are, but I believe we can work around that. On the early Brockway chassis records, the Fuller 5 speed transmissions typically had 4 drive teeth and 15 driven teeth.

This is from a ‘63 155T, but it’s the same for my ’55 155W, ’46 260XW, etc...

To determine the gears in the RT910, I went through a Parts Manual I bought off of eBay a number of years ago. It was for the 1970 Sears Oil E361T’s, which included my Dad’s truck. Sure enough on the very last page in the manual I found this...

So for the RT910 the drive gear has 4 teeth and the drive gear has 14 teeth.

More to follow...

-

After a further Google search I found the ring and pinion number listed on Weller’s Truck website. They have a great catalog online...

http://www.wellertruck.com/lit/Weller_Diff_Catalog_2011.pdf

But for the ring gear I had, it was listed for an Eaton 19201 rear (and 19501 if its locked in low range...) The only difference here is that my carrier has 16 spine axles instead of 22. Weller did not have 5.43’s in their inventory but they were very helpful when I talked to them.

I did get several suggestions on locating gears. I called a few local places along with Pat at Demo’s but he only had 6.14’s. Then a guy on FB referred me to Tommy John’s Truck Parts in Wortsburo, NY . John didn’t have any gears but he referred me to A&A Truck Parts in Freehold, NJ and sure enough he had a set in an International pumpkin. For some reason International used 10 hole pumpkins instead of the 12 hole, but the gears are the same. So after a handful of conversations, I made a trip to Freehold which I was able to do during one of my New Brunswick trips for work. I did get some strange looks when I pulled in the yard with a rental car and popped the truck open

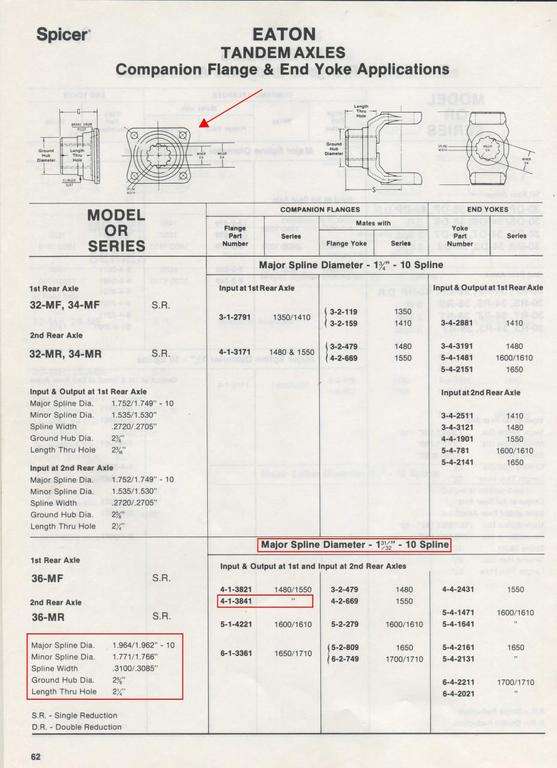

The first thing I noticed was that the companion flange (yoke) was different. It’s actually a Rockwell yoke for a wing bearing, 72N series. But after I removed the flange from pinion, I realized that the splined parts of the pinions were different diameters.

Damn (again...)

The inner and outer bearings were the same for both yokes and the shims and spacers were the same, but the original pinion was 10 spline with 1.750” major diameter while the new one was also 10 splines but with a 1.964” major diameter. So this added another level to my companion flange dilemma...

Before I realized there was a difference in the pinions, I figured I would re-use the companion flange from the 6.71 pinion. My original driveshaft used Spicer 1500 series U joints. These have been obsolete for some time but I was able to locate an NOS pair on eBay a number of years ago. On a side note, Neapco has started making these joints again. The Spicer number was 5-115X and the new Neapco number is 3-0055.

Then I considered using the Rockewell 72N flange. One of my International buddies (Kevin L) had a driveshaft I could use but that would mean I would have to have the driveshaft cut and have new yoke welded on, and then buy a new wing u joint. But before I went down that path, I figured I would try to locate a companion flange to match my Spicer 1500 joint. Besides, both u joints were new (well from 2008...) and the flange the u joint goes into was also new.

After searching online with no luck, I remember Jack Alt have given me a vintage Spicer book years ago. So I dug that out and was able to find a number that matched was I needed, Spicer #4-1-3841.

Although the flange was listed for a 1480 or 1550 joint, the dimensions matched my 1500 series flange, with a ground flange diameter of 2 5/8” and a length through the hole at 2 1/4". Of course this flange has been obsolete for some time, I after a quick Google search I found that Weller had one in stock in Grand Rapids Michigan. I called the next day and it was the last one they had, still covered in cosmoline and wrapped in wax paper. It cost a few bucks but was still cheaper than having the drive shaft cut...

And now I had a nice assortment of companion flanges... On a side note, the round flange was from the 257 rear. This took (8) 3/8” bolts and a Spicer 1610 series joint, Spicer number 5-279X.

More to follow...

-

2

2

-

Looking for T427 or U501 Continental Engine(s)

in Brockway Trucks

Posted

Hi Gary...

For Continental parts I usually deal with Jerry Moons at Montes Equipment. This is their website...

http://montesequipment.com/

The T427 is an overhead valve motor that came out in the late 50's maybe? I may know of a T427 in a fire truck in Scranton.

Tom